SOLDER PALLET HOLD-DOWNS

Hold-Down Clamps

* Solder Pallet Hold-Downs: Essential for PCB Assembly

Solder pallet hold-downs are key components used in the PCB (Printed Circuit Board) assembly process, particularly in soldering and surface mount technology (SMT) operations. These hold-downs ensure that the PCB or the solder pallet remains firmly in place during soldering, preventing movement or shifting, which could lead to defects or poor-quality solder joints.

Solder pallet hold-downs come in various designs depending on the type of PCB, the size and complexity of the assembly, and the soldering technique used (e.g., wave soldering, reflow soldering, or hand soldering).

Key Functions of Solder Pallet Hold-Downs

Secure Positioning:

- Solder pallet hold-downs keep the PCBor solder pallet in a stable position throughout the soldering process, ensuring that components are soldered correctly and without any misalignment.

- They help prevent movement caused by forces such as air pressure, vibrations, or mechanical handling.

Preventing Warping:

- During the soldering process, heat can cause warping or distortion of the PCB. Hold-downs apply even pressure to the PCB to prevent this, maintaining flatness and ensuring the integrity of the assembly.

Improved Soldering Accuracy:

- By keeping the PCB secure, hold-downs ensure that components are soldered accurately and that the solder joints are formed properly. This reduces the likelihood of cold solder joints, bridging, or component misplacement.

Supporting Automated Soldering Processes:

- In automated soldering systems, such as those used in wave soldering or reflow soldering, hold-downs are essential for stabilizing the solder pallet. They help the machine process the PCB consistently and with high precision.

Advantage

Increased Production Efficiency:

- By keeping the PCB securely in place, hold-downs prevent rework caused by misalignment or movement during soldering. This leads to faster and more consistent assembly processes, reducing the overall production time.

Enhanced Quality Control:

- Hold-downs help ensure that solder joints are correctly formed, improving the overall quality and reliability of the PCB. Properly soldered connections reduce the likelihood of component failures or issues during operation.

Reduced Defects:

- By stabilizing the PCB and preventing it from shifting during the soldering process, hold-downs reduce the occurrence of defects such as cold solder joints, bridging, or misaligned components.

Cost-Effective:

- Using the right hold-down mechanism can reduce the amount of time and labor spent on rework or inspection, leading to lower production costs and better overall profitability.

Adaptability:

- Many solder pallet hold-downs are adjustable or customizable to fit a wide variety of PCB sizes and shapes, providing flexibility across different types of projects or production runs.

When selecting a solder pallet hold-down, it’s important to consider the following factors:

- PCB Size and Shape: Choose a hold-down that accommodates the dimensions and shape of your PCB to provide an even and secure hold.

- Soldering Process: The type of soldering process (e.g., wave soldering, reflow soldering, hand soldering) will dictate the type of hold-down best suited for your needs.

- Automation: For automated systems, vacuum or spring-loaded hold-downs may be ideal due to their ability to securely hold PCBs during high-speed, automated operations.

- Precision Needs: If precise soldering is crucial, a vacuum hold-down or custom fixture may be required for higher accuracy.

- Material: Ensure the material of the hold-down is compatible with the PCB and the environment in which it will be used, especially for heat-sensitive or delicate components.

Solder pallet hold-downs are an essential part of the PCB assembly process, ensuring that the PCB remains secure during soldering, thereby enhancing the quality, precision, and efficiency of the entire operation. Whether you are working with automated soldering systems or manual soldering techniques, choosing the appropriate hold-down system is key to achieving optimal soldering results.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.

Related Products

T301

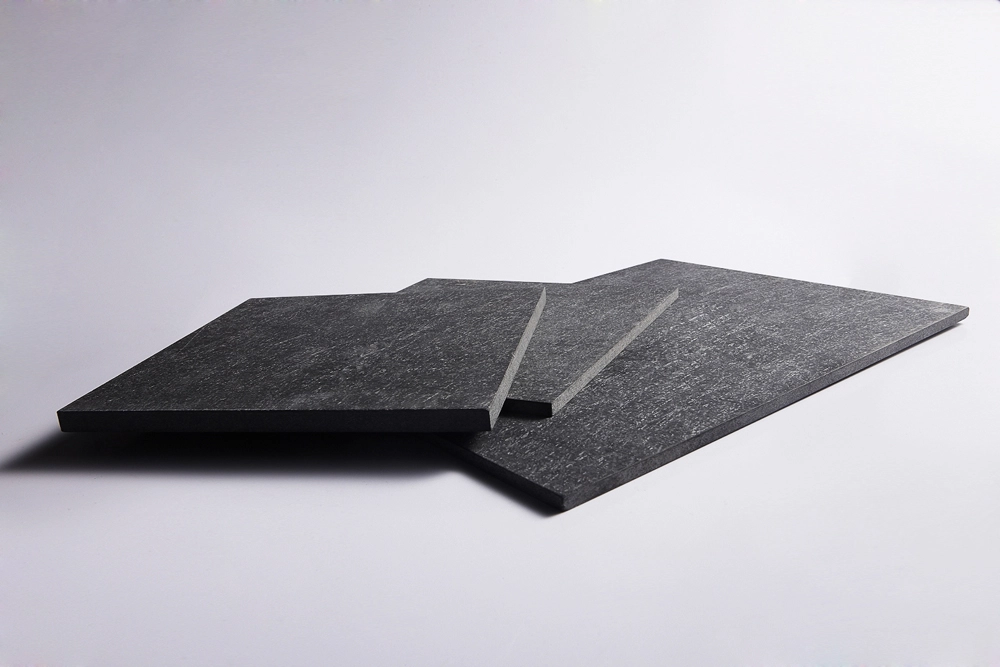

Solder Pallet Materials

T315

Solder Pallet Materials

T311 (G10)

Insulating Materials

T312 (FR4)

Insulating Materials