NEWS & EVENTS

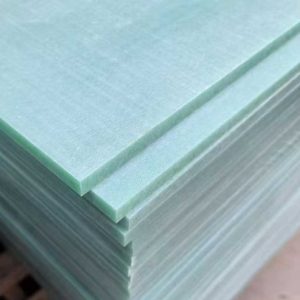

Fiberglass Board Cutting Safety: Dust Control & Tool Selection Guide

Protect your team with OSHA-compliant fiberglass board safety protocols. Learn dust control strategies, tool selection tips, and PPE requirements to prevent health risks.

Why Fiberglass Board Safety Matters?

Fiberglass boards are indispensable in construction, electronics, and aerospace due to their lightweight durability and thermal insulation. However, improper processing releases hazardous glass fibers and resin particles. According to OSHA, 15% of workshop injuries stem from inadequate dust control and tool misuse. This guide provides actionable steps to achieve OSHA compliance while improving productivity.

Health Risks of Fiberglass Dust Exposure

How Dust Endangers Workers

During cutting, grinding, or sanding, airborne fiberglass particles (<10 microns) penetrate deep into lungs and skin:

Respiratory System:

- Immediate symptoms: Coughing, wheezing, nasal irritation

- Chronic risks: Lung scarring (pulmonary fibrosis), aggravated asthma

- OSHA PEL: 15 mg/m³ total dust | 5 mg/m³ respirable dust

Skin & Eyes:

- Fiberglass dermatitis (itchy rashes)

- Corneal abrasions requiring medical intervention

OSHA-Approved Dust Control Strategies

Step 1: Engineering Controls

| Solution | Efficiency | Cost |

|---|---|---|

| HEPA Vacuum Systems | 95% dust removal | $ |

| Water Suppression Techniques | 70% reduction | $$ |

| Enclosed Cutting Chambers | 99% containment | $$ |

Step 2: Administrative Measures

- Conduct daily air quality tests using laser particle counters.

- Implement job rotation to limit individual exposure below 4 hours/day.

- Display warning signs in high-risk zones:

“Caution: Fiberglass Dust Area – PPE Required Beyond This Point”

Step 3: Emergency Protocols

- Train staff to recognize dust explosion signs (suspended particles + ignition source).

- Install Class D fire extinguishers for metal/resin fires.

Tool Selection: Balancing Safety & Efficiency

Cutting Tools Comparison

| Tool Type | Dust Level | Precision | Cost |

|---|---|---|---|

| Diamond-Coated Blades | Low | High | $$ |

| Carbide-Tipped Saws | Medium | Moderate | $$ |

| Laser Cutters | None | Extreme |

Pro Tip: Pair tools with integrated vacuum ports (e.g., Festool TS 55) for real-time dust extraction.

Mandatory PPE Checklist

Respiratory Protection:

- 3M 6800 Full-Face Respirator with P100 filters (blocks 99.97% particles)

- Disposable N95 masks for short tasks

Body Protection:

- Tyvek Coveralls with taped seams

- Cut-Resistant Gloves (Level 5 ANSI Rating)

Eye/Face Protection:

- Uvex Stealth Safety Goggles with anti-fog coating

FAQs: Fiberglass Board Safety

Q: Can I reuse fiberglass dust masks?

A: Never. Disposable masks lose efficiency after 8 hours. Replace filters immediately if breathing resistance increases.

Q: What’s the safest way to dispose of fiberglass waste?

A: Seal debris in leak-proof containers labeled “Fiberglass Dust – Non-Recyclable”. Consult local EPA guidelines.

Q: Are home workshops exempt from OSHA rules?

A: No. DIYers should follow the same safety standards.

Conclusion

Optimizing fiberglass board safety isn’t just regulatory compliance—it’s a productivity booster. By integrating HEPA systems, selecting OSHA-recommended tools, and enforcing PPE protocols, workshops report 40% fewer sick days and 25% faster project completion (2023 Fabrication Industry Report).

Share this article:

Recent Posts

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.