NEWS & EVENTS

FR-4 vs. G-10: Deciphering the Differences in Fiberglass Epoxy Laminates for PCB and Mechanical Applications

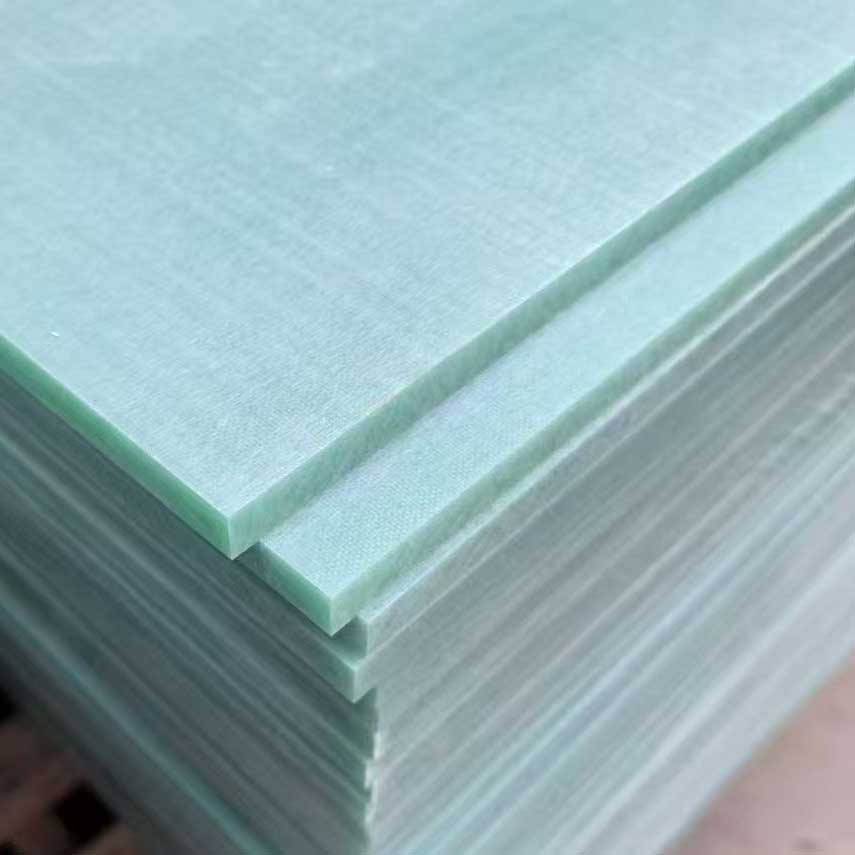

In the world of electronics manufacturing, mechanical engineering, and specialized gear, FR-4 and G-10 are two frequently encountered, yet often confused, material designations. Both belong to the family of Fiberglass Epoxy Laminates, sharing a common foundation of high strength and electrical insulation. However, a single, critical distinction—flame retardancy—diverges their applications and technical roles.

For engineers, product designers, and hobbyists, understanding the nuances between these two industrial mainstays is crucial for correct material selection. This optimized guide breaks down the essence, technical specifications, and distinct application landscapes of FR-4 and G-10.

Common Origin: The Foundation of Fiberglass Epoxy

At their core, FR-4 and G-10 are fundamentally the same type of material, known generically as a Thermoset Composite Material. This shared structure provides their impressive baseline properties:

Reinforcement: Continuous woven Fiberglass Cloth (Glass Fabric). This provides exceptional mechanical strength, rigidity, and dimensional stability.

Matrix: Epoxy Resin. This thermosetting polymer binds the fiberglass layers, offering superior electrical insulation, moisture resistance, and chemical resistance.

This robust combination means both materials inherit excellent mechanical strength, reliable electrical insulation, and superior moisture and humidity resistance, making them prime candidates for demanding industrial use.

The Ultimate Difference: Flame Retardancy & NEMA Standards

The core feature that separates these two materials—and defines their primary application—is their compliance with flame safety standards, specifically those set by NEMA (National Electrical Manufacturers Association).

FR-4: The Electronic Safety Standard (Flame Retardant)

FR-4 is the required material for nearly all modern electronic circuit boards.

Meaning: FR stands for “Flame Retardant.” The designation “4” refers to the specific grade of glass-reinforced epoxy.

Key Feature (SEO Focus): FR-4 is engineered to meet the stringent UL94-V0 fire safety standard. This means the material is self-extinguishing; it will stop burning within 10 seconds after the flame source is removed.

How it’s Achieved: The resin system is fortified with effective flame retardants (historically brominated, now often halogen-free alternatives).

Primary Application: The essential substrate for Printed Circuit Boards (PCBs) in computers, smartphones, communication gear, and industrial control systems.

Appearance: Typically characterized by a unique yellow-green or light-brown color.

G-10: The Mechanical Workhorse (Non-Flame Retardant)

G-10 is the original, basic grade of the material, prioritized for its maximum mechanical performance over fire safety.

Key Feature: G-10 does not meet the UL94-V0 self-extinguishing standard and is considered combustible.

Performance Advantage: Since the epoxy resin is not altered with flame retardants, G-10 often boasts slightly superior mechanical properties like interlaminar shear strength and impact resistance compared to conventional FR-4 (though this gap is shrinking with modern FR-4 technology).

Primary Application: Used in specialized structural components where high strength and moisture resistance are critical, but fire safety is not a primary concern.

Appearance: Easily available in a wide variety of colors (black, white, blue, red) because the absence of flame retardants allows pigments to be added without compromising performance.

Common Use: Frequently found in knife handles (often called G-10 scales), structural shims, spacers, and highly durable parts for machinery.

FR-4 vs. G-10: Comparative Technical Specifications

This table offers a clear, structured comparison crucial for engineers and designers.

| Feature | FR-4 (The PCB Standard) | G-10 (The Mechanical Standard) |

| Material Class | Fiberglass Epoxy Laminate | Fiberglass Epoxy Laminate |

| Flame Retardancy | Yes (Meets UL94-V0 – Self-extinguishing) | No (Combustible/Non-self-extinguishing) |

| Primary Driver | Safety (Preventing fire spread) | Mechanical Strength (Structural integrity) |

| Typical Appearance | Yellow-Green, Light Brown | Black, White, Blue, Red (Diverse colors) |

| Primary Industry | Electronics (PCBs, Motherboards) | Cutlery, Machinery, Aerospace, Instruments |

| Electrical Insulation | Excellent (Optimized for high-frequency PCBs) | Excellent (General purpose) |

Application Scenarios: Where Each Material Excels

The fundamental difference in flame safety creates two distinct application territories for these excellent materials.

FR-4 Applications (PCB & Safety Critical)

The primary role of FR-4 is as the foundation for the digital world.

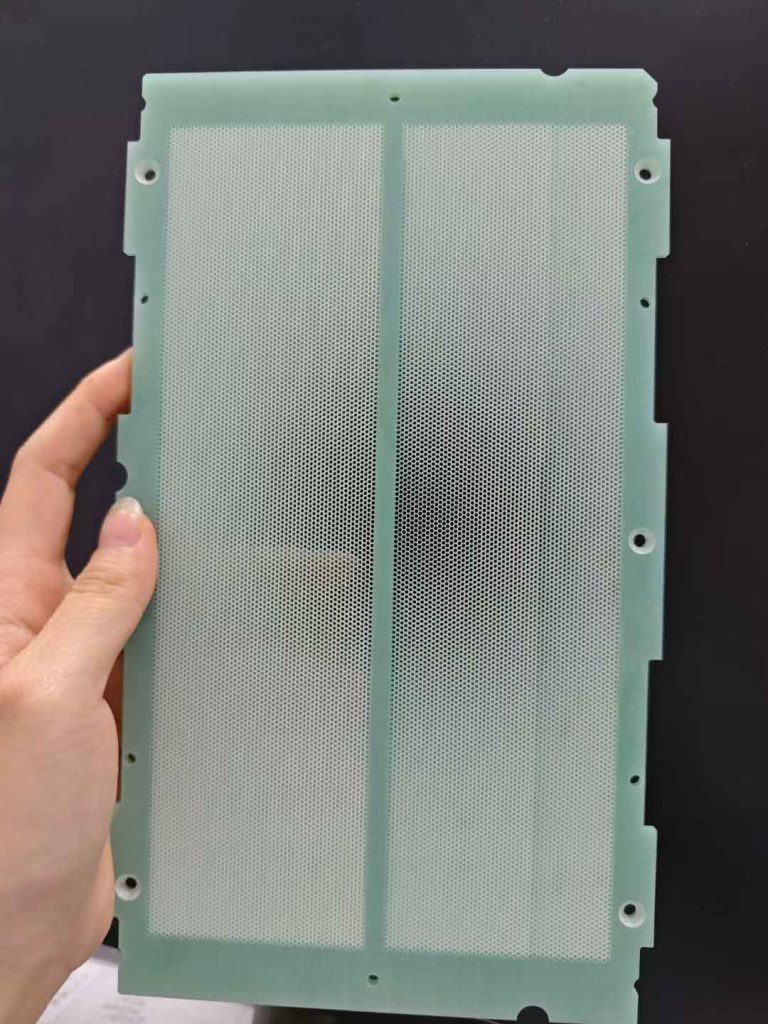

Printed Circuit Boards (PCBs): Used for single-sided, double-sided, and multi-layer boards in nearly every electronic device globally (smartphones, automotive systems, servers, laptops).

Insulation Barriers: Used as electrical insulation in motors, transformers, and switchgear where self-extinguishing properties are mandated by code.

G-10 Applications (Strength & Aesthetics)

G-10 thrives in areas that prioritize mechanical performance, light weight, and aesthetic versatility.

Knife Handles (G-10 Scales): A top choice for tactical and utility knife handles due to its superior durability, moisture resistance, and ability to be colored and textured.

Structural Components: Used for insulating washers, high-strength support brackets, and specialized industrial shims.

Hobby & Sport: Common in drone frames, RC components, and high-end archery or fishing gear where lightweight strength and rigidity are required.

Conclusion

FR-4 and G-10 are both high-performance fiberglass epoxy composites, but their defining characteristic—flame retardancy—determines their ultimate purpose. FR-4 is the safety-mandated cornerstone of electronics (PCBs), while G-10 is the high-strength, durable choice for structural and mechanical applications (knife handles, industrial components). Choosing the right material depends entirely on whether your application requires the UL94-V0 standard for fire safety (FR-4) or the maximum possible mechanical resilience (G-10).

Related Topics

Explore these topics to learn more about advanced materials and their applications in modern industries!

Share this article:

Recent Posts

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.