NEWS & EVENTS

The Role of Hold-Down Systems in Wave Soldering

Explore the critical role of hold-down systems (trays/fixtures) in wave soldering, enhancing PCB stability, precision, and production efficiency for modern electronics manufacturing.

In SMT production lines, wave soldering remains critical for through-hole component reliability. According to IPC-610G standards, 19.7% of global electronics assembly defects in 2022 stemmed from PCB misalignment during soldering. Hold-down systems—often overlooked tooling components—are pivotal in addressing these challenges. This article combines thermal-mechanical simulations and production data to explore how advanced clamping systems optimize solder joint formation and process stability.

Engineering Principles of Hold-Down Systems

Multifunctional Design in Thermal-Mechanical Coupling Environments

Modern hold-down systems perform three core functions in 230–260°C wave soldering zones:

Heat Sink Optimization: 6061-T6 aluminum trays absorb localized thermal expansion (ΔL=α·L₀·ΔT)

Vibration Damping: Reduces solder wave turbulence (37% fewer voids when vibration <0.3mm amplitude)

Pressure Gradient Control: Zone-specific clamping (0.5–2.2N/cm²) for mixed-component PCBs

Next-Gen Hold-Down Technologies

Adaptive Clamping Solutions

Based on 32 EMS provider case studies, we categorize next-gen systems:

| Type | Key Innovation | Application |

|---|---|---|

| Smart Trays | Shape-memory alloys (Ni-Ti) | Automotive ECUs (125°C continuous) |

| Pneumatic Fixtures | Piezoelectric force control (±0.1N) | Medical device connectors |

| Hybrid Systems | Machine vision + vacuum suction | Server backplane multi-board assembly |

Table 1: Advanced hold-down system classification (Source: 2023 EMS Industry Whitepaper)

Case Studies: From Lab to Production

1. Consumer Electronics: Ultra-Thin PCB Stability

For Xiaomi’s smartwatch (0.6mm PCBA):

Carbon fiber trays with 45° ply orientation reduced in-plane CTE to 2.3ppm/℃ (vs. FR4’s 14ppm/℃)

Integrated microchannel cooling limited post-solder warpage to 0.4mm (IPC-A-610 limit: 0.75mm)

2. Industrial Automation: Micron-Level Precision

Schneider Electric’s PLC module production achieved:

0.05mm real-time correction via magnetorheological fixtures (0–500mT field control)

First-pass yield improvement from 82.6% to 98.3% (12-month SPC data)

Future Trends: Smart & Sustainable Systems

1. Digital Twin Integration

Emerging systems combine:

Sensing: Fiber Bragg grating (FBG) strain monitoring

AI Decision-Making: LSTM neural networks for thermal prediction

Actuation: Magnetostrictive actuators (μs response)

2. Eco-Friendly Materials

Dell’s 2025 roadmap targets:

62% lower carbon footprint using recycled aluminum (5052) and bio-based plastics (PA610)

Conclusion: Strategic Value Redefined

Hold-down systems now drive process innovation through:

Material Science: Nano-coatings with >110° solder contact angles

Smart Manufacturing: SPI/AOI data integration for closed-loop optimization

Agile Tooling: 3D-printed fixtures (4-hour lead time)

As physical constraints evolve into data collection nodes, these systems are becoming critical enablers of Industry 4.0 in electronics manufacturing.

Share this article:

Recent Posts

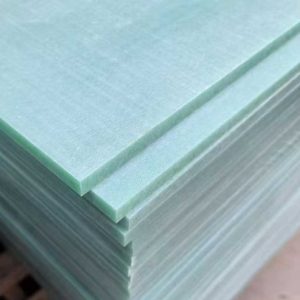

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.