NEWS & EVENTS

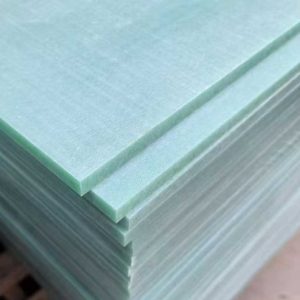

FR4 vs. G10: A Deep Dive into Properties, Applications & Differences

This comprehensive analysis compares FR4 and G10 materials, exploring their properties, applications, and key differences to help you choose the right option for your project.

Introduction

In modern electronics and advanced manufacturing, FR4 and G10 are two critical materials widely used in PCB fabrication, electrical insulation, and mechanical support. Although both are epoxy-based composites, their performance characteristics and applications differ significantly. This article explores their distinctions in material composition, core properties, applications, and comparative analysis, providing valuable insights for engineers and manufacturers.

FR4 Material: Roles and Characteristics

1. Material Definition and Composition

FR4 (Flame Retardant 4) is a flame-retardant epoxy laminate compliant with the NEMA LI 1-1998 standard. Its core components include:

Matrix Resin: Bisphenol-A epoxy resin (30–40% by weight)

Reinforcement: E-glass fiber cloth (60–70% by weight)

Flame Retardants: Tetrabromobisphenol-A (TBBPA, ~15%)

Curing Agents: Dicyandiamide (DDS) or phenolic resins

2. Key Properties

Flame Retardancy: Certified to UL94 V-0, limiting oxygen index (LOI) ≥32%

Electrical Performance: Dielectric constant (Dk) 4.3–4.9 @1MHz, dissipation factor (Df) 0.02–0.03 @1GHz

Mechanical Strength: Flexural strength ≥400 MPa, elastic modulus ≥20 GPa

Thermal Performance: Tg 130–180°C, Z-axis coefficient of thermal expansion (CTE) 12–16 ppm/°C

Environmental Resistance: 85°C/85% RH 1000-hour humidity test; CAF resistance >500 hours

3. Typical Applications

Consumer Electronics: Smartphone motherboards, laptop PCBs

Industrial Controls: PLC controllers, motor driver insulation boards

Automotive Electronics: ECU control module substrates

Telecom Equipment: 4G base station RF front-end boards

G10 Material: Roles and Characteristics

1. Material Definition and Composition

G10 is a non-flame-retardant glass fiber-reinforced epoxy laminate defined by the NEMA standard. Key differences from FR4 include:

No Halogenated Flame Retardants

Higher Epoxy Resin Content (35–45%)

Denser 7628-Type Glass Fabric (Single-Layer Thickness 0.18mm)

2. Key Properties

Mechanical Performance: Flexural strength up to 550 MPa, 20% higher impact toughness than FR4

Electrical Performance: Volume resistivity >10¹⁴ Ω·cm, Df ≈0.025 @1MHz

Thermal Performance: Tg 110–130°C, lower thermal stability than FR4

Environmental Properties: Halogen-free but lower arc resistance (30–50 sec vs. FR4’s >100 sec)

3. Typical Applications

Electrical Insulation: High-voltage switch insulation pads, transformer barriers

Mechanical Structures: Drone frames, precision instrument brackets

Special Environments: Underwater equipment seals

Prototyping: CNC-machined models

Core Differences Between FR4 and G10

1. Flame Retardancy Comparison

| Parameter | FR4 | G10 |

|---|---|---|

| UL94 Rating | V-0 | HB (Combustible) |

| LOI | ≥32% | 21–23% |

| Residue Formation | Chars to block oxygen | No self-extinguishing |

2. Mechanical Performance Comparison

| Parameter | FR4 | G10 |

| Flexural Strength | 400–450 MPa | 500–550 MPa |

| Elastic Modulus | 20–22 GPa | 24–26 GPa |

| Impact Toughness | 90–110 J/m² | 130–150 J/m² |

3. Electrical Performance Comparison

| Parameter | FR4 | G10 |

| Dk @1MHz | 4.3–4.9 | 4.8–5.2 |

| Df @1GHz | 0.020–0.025 | 0.025–0.030 |

| Arc Resistance | 120–180 sec | 40–60 sec |

4. Thermal Performance Comparison

| Parameter | FR4 | G10 |

| Tg | 130–180°C | 110–130°C |

| Z-CTE | 12–16 ppm/°C | 18–22 ppm/°C |

| Thermal Conductivity | 0.30 W/m·K | 0.25 W/m·K |

Selection Guidelines

Scenario 1: Consumer Electronics

Requirement: Flame retardancy, cost efficiency

Choice: Standard FR4 (e.g., Shengyi S1141)

Rationale: UL94 V-0 compliance is mandatory

Scenario 2: Industrial Structural Parts

Requirement: High mechanical strength, no flame retardancy

Choice: G10 (e.g., Garolite G10)

Rationale: 25% higher flexural strength, 18% cost reduction

Scenario 3: Hybrid Applications (e.g., EV Chargers)

Requirement: Flame retardancy + heat dissipation + structural strength

Choice: FR4 (Tg170) + aluminum substrate hybrid design

Rationale: FR4 ensures safety compliance; metal substrates enhance cooling

Industry Trends

1. Eco-Friendly FR4

Halogen-free FR4 (e.g., Isola DE104) is growing at 12% annually, replacing traditional brominated grades

2. Modified G10

Carbon fiber-enhanced G10 (CCG10) achieves 0.8 W/m·K thermal conductivity, expanding into thermal management

3. Hybrid Laminates

FR4/G10 hybrid stacks combine flame retardancy and mechanical strength in single panels

Conclusion

The fundamental distinction between FR4 and G10 lies in their flame retardancy systems, leading to differences in safety standards, mechanical properties, and applications. Engineers should prioritize:

FR4 for safety-critical scenarios

G10 for mechanical components to reduce costs

Df evaluation for high-frequency circuits

CTE and Tg validation in humid environments

Future materials may merge flame retardancy and ultra-high strength, but FR4 and G10 remain indispensable today. For critical projects, perform TMA (thermomechanical analysis) and DSC (differential scanning calorimetry) tests to ensure optimal material selection.

Related Topics

Explore these topics to learn more about advanced materials and their applications in modern industries!

Share this article:

Recent Posts

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.