NEWS & EVENTS

Optimizing Efficiency with Solder Pallets in Reflow Soldering

Solder pallets enhance reflow soldering efficiency by securely holding PCBs in place, reducing defects, and ensuring uniform heat distribution for high-quality solder joints.

Reflow soldering is a critical process in modern electronics manufacturing, enabling precise and reliable connections between electronic components and printed circuit boards (PCBs). Among the tools that enhance this process, solder pallets stand out as essential fixtures. These specialized tools significantly improve efficiency, precision, and reliability in reflow soldering. In this comprehensive guide, we explore the role, applications, and benefits of solder pallets in advanced electronics manufacturing.

What Are Solder Pallets?

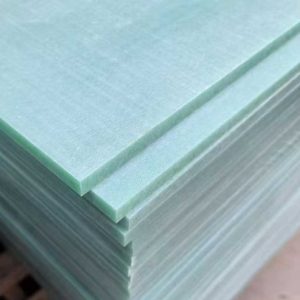

Solder pallets, also known as solder carriers or fixtures, are precision-engineered tools designed to securely hold PCBs during the reflow soldering process. Crafted from high-temperature-resistant materials such as glass-reinforced epoxy composites or advanced thermoset plastics, these pallets withstand the intense heat inside reflow ovens, which can reach up to 250°C.

Key Applications of Solder Pallets in Reflow Soldering

1. Protecting Heat-Sensitive Components

Reflow soldering involves heating the entire PCB to melt solder paste and create electrical connections. Some components, such as plastic connectors, optoelectronic devices, or lithium batteries, are highly sensitive to heat.

Solder pallets shield these components by masking them or reducing their direct exposure to the heat generated in the reflow oven, ensuring their integrity while enabling effective soldering for other components.

2. Selective Soldering for Complex Boards

In complex PCB assemblies, not all areas require soldering. Solder pallets define soldering zones by masking specific areas, preventing solder paste from being applied unnecessarily.

This is especially valuable for mixed-technology PCBs that combine through-hole and surface-mount components.

3. Stabilizing Double-Sided Assemblies

Double-sided PCBs feature components on both sides, posing unique challenges during reflow soldering. Components on the underside may become dislodged due to gravity and heat.

Solder pallets secure these components with custom-cut cavities that match their profiles, ensuring stability throughout the process.

4. Ensuring Uniform Thermal Management

Uniform heat distribution is crucial to avoid defects like solder voids, cold joints, or thermal stress. Solder pallets promote even heat transfer across the PCB.

Some designs include features like heat sinks or thermal shields to manage temperature variations in boards with uneven component density.

5. Supporting Miniaturized Component Placement

- As electronic devices become smaller and more complex, PCBs feature tiny components with precise placement requirements. Solder pallets provide alignment and support to prevent movement or misalignment during reflow soldering.

Advantages of Using Solder Pallets in Reflow Soldering

1. Enhanced Quality Control

Solder pallets minimize defects such as solder bridges, tombstoning, and voids by ensuring component stability, shielding sensitive parts, and promoting uniform heat distribution. This leads to more reliable PCBs and fewer failures.

2. Boosting Production Efficiency

By enabling batch processing of multiple PCBs, solder pallets reduce cycle times and enhance production efficiency. Streamlined handling minimizes downtime and operator intervention.

3. Reducing Rework and Scrap Rates

Solder pallets help prevent defects that require costly rework, lowering scrap rates and saving time and resources.

4. Customizable for Specific Needs

Tailored designs accommodate unique PCB shapes, component configurations, and process parameters, ensuring compatibility with diverse manufacturing requirements.

5. Improved Operator Safety

High temperatures in reflow soldering pose risks to operators. Solder pallets provide a secure handling method, reducing the likelihood of burns or injuries.

Applications of Solder Pallets in Key Industries of Solder Pallets

1. Consumer Electronics Manufacturing

In devices like smartphones, laptops, and wearables, solder pallets ensure precise assembly of densely packed PCBs, meeting the high-quality demands of consumer electronics.

2. Automotive Electronics Production

Automotive systems such as engine control units (ECUs) and advanced driver-assistance systems (ADAS) rely on robust PCBs. Solder pallets facilitate defect-free soldering to ensure durability and performance.

3. Medical Device Assembly

Precision and reliability are critical for medical devices like pacemakers and diagnostic equipment. Solder pallets support flawless assembly processes, meeting stringent quality standards.

4. Aerospace and Defense Electronics

Aerospace and defense applications demand high-reliability electronics for avionics and communication systems. Solder pallets ensure the precision and durability needed for these environments

5. Industrial Automation Components

In controllers, sensors, and actuators, solder pallets maintain consistency and durability, essential for industrial automation systems.

Advanced Features of Modern Solder Pallets

1. Innovative Material Solutions

Advanced composites with enhanced thermal stability and durability improve solder pallet performance, extending their lifespan and cost-effectiveness.

2. Enhanced Design Features

Modern designs incorporate features like spring-loaded clamps, vacuum systems, and alignment pins to enhance functionality and ease of use.

3. Automation Compatibility

Designed for seamless integration with robotic systems and conveyor belts, solder pallets support advanced manufacturing technologies, including Industry 4.0.

4. Sustainability Initiatives

Manufacturers are adopting sustainable materials and energy-efficient practices in solder pallet production, aligning with environmental goals.

Conclusion

Solder pallets are indispensable tools in reflow soldering, providing precision, protection, and efficiency. Their ability to address challenges such as handling miniaturized components and ensuring defect-free soldering makes them essential in industries ranging from consumer electronics to aerospace. As technology advances, solder pallets will continue to play a vital role in achieving high-performance, reliable electronic assemblies. Explore our detailed guides and resources to optimize your soldering processes and stay ahead in the competitive electronics industry.

Share this article:

Recent Posts

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.