NEWS & EVENTS

Wave Soldering Fixture Maintenance Guide: 5 Proven Strategies

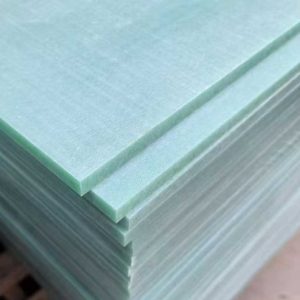

Learn proven methods to clean wave soldering fixtures, eliminate flux residue, and reduce defects. Compare synthetic stone (Durostone) vs. lead-free stone (Ricocel) maintenance. Increase yield by 30%!

Why Proper Fixture Cleaning Matters

Hidden Costs of Contamination

Defect Rate Surge: Residual flux forms insulating layers, increasing voiding rates by 8–12%.

Shortened Fixture Life: Acidic residues corrode materials like fiberglass, doubling replacement costs.

Production Downtime: Cleaning delays cost $10k+/year for mid-sized lines.

Pro Tip: A 0.1mm dross layer can cause 15% soldering defects – regular cleaning is non-negotiable.

3-Step Cleaning System (By Contamination Level)

Step 1: Daily Maintenance (5 Minutes/Shift)

1. Tools:

- Ceramic scraper (45° angle)

- Nanofiber cloth + 99% IPA

- Magnetic dross collector ($150)

2. Process:

- Wipe warm fixtures (60–80°C) to soften residues.

- Use magnet to capture loose solder particles.

- Blow debris with low-pressure air (<0.3MPa).

Step 2: Weekly Deep Clean

1. Best for: Stubborn flux carbonization on synthetic stone (Durostone).

2. Method:

- Aqueous Vacuum Cleaner: Removes 95% of contaminants with pH 9.5 alkaline spray (40°C).

- Cycle Time: 15 minutes/fixture.

3. Cost: 0.20/cleaningvs.0.20/cleaningvs.2.50 manual labor.

Step 3: Emergency Heavy Contamination

1. Laser + Plasma Combo:

- Green Laser (532nm): Vaporizes organic flux at 50W power.

- Low-Temperature Plasma: Breaks down metal oxides without damaging lead-free stone (Ricocel).

2. ROI: 99.1% QFN yield was achieved in the defense manufacturing case study.

Material-Specific Cleaning Guide

| Material | Optimal Method | Avoid | Cost/Year |

|---|---|---|---|

| Synthetic Stone | Aqueous vacuum (≤0.5Bar) | Ultrasonic >200W | $1,200 |

| Lead-Free Stone | Plasma + alcohol wipe | pH >10 cleaners | $800 |

| Titanium | Dry ice blasting (3mm grit) | HF acid | $2,500 |

Key Takeaway: Ricocel’s nano-coatings reduce cleaning frequency by 3x vs. Durostone.

Top 4 Innovations to Slash Cleaning Time

Self-Cleaning Coatings:

Superhydrophobic textures (contact angle >150°) repel flux.

Result: 60% less residue on Ricocel fixtures.

AI-Powered Monitoring:

LIBS sensors trigger alerts when Sn/C thresholds exceed 5%.

Enzyme Cleaners:

Citrus-based solvents cut VOC emissions 90% (EPA compliant).

Predictive Maintenance:

Machine learning forecasts cleaning needs (±2hr accuracy).

FAQ: Wave Soldering Fixture Cleaning

Q1: How often should I clean fixtures?

Durostone: Every 5,000 cycles (weekly).

Ricocel: Every 10,000 cycles (bi-weekly).

Q2: Can I use acetone on lead-free stone?

No! Acetone degrades Ricocel’s anti-static coating – use 70% ethanol instead.

Q3: What’s the cheapest way to remove solder dross?

Magnetic collectors ($150) capture 97% loose particles, reducing manual scrubbing.

Conclusion: Cleaner Fixtures = Higher Profits

Upgrading from reactive scrubbing to smart cleaning systems can boost yield by 30% and extend fixture lifespan by 2 years. Whether you use Durostone or Ricocel, adopt these strategies to turn maintenance from a cost center into a quality asset.

Share this article:

Recent Posts

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Leave a message

* Thank you for visiting our website. We hope you found the information you were seeking.

* If you have any questions about our products, pricing, or would like to schedule a consultation, please contact us.