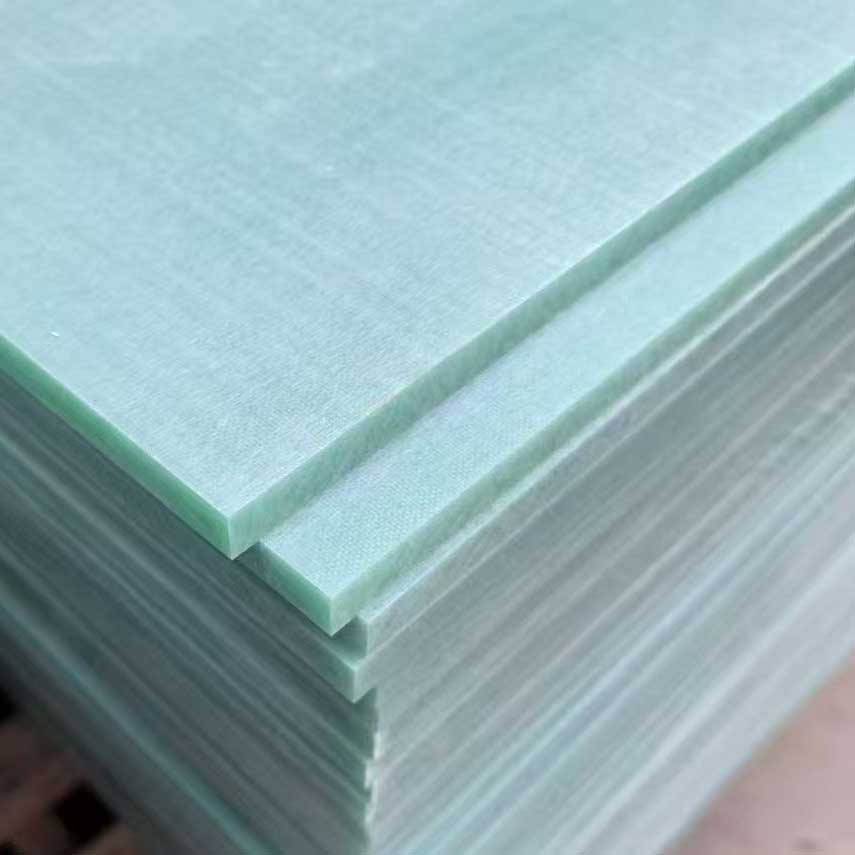

FR-4 and G-10: Flame Retardancy, Strength, and Applications

FR-4 vs. G-10 difference deciphered. Learn why FR-4 is the required PCB material, and how G-10 excels in mechanical strength for structural parts.

How to Validate Reflow Soldering Fixture Designs?

Learn how to verify the rationality of reflow soldering fixture design and the necessary tests. Understand the importance of design verification.

Titanium in Electronics: Smarter Wave Soldering Solutions

Discover how titanium alloy wave soldering fixtures enhance electronics manufacturing with unmatched thermal stability, corrosion resistance, and 10-year lifespan. Explore technical advantages, cost analysis, and aerospace/automotive case studies.

Fiberglass Board Cutting Safety: Dust Control & Tool Selection Guide

Learn essential safety protocols for fiberglass board processing, including dust protection, tool selection, and OSHA compliance. Prevent health risks and improve workplace efficiency.

The Role of Hold-Down Systems in Wave Soldering

Explore the critical role of hold-down systems (trays/fixtures) in wave soldering, enhancing PCB stability, precision, and production efficiency for modern electronics manufacturing.

Wave Soldering Bridging Solutions: How Fixture Design Flaws Cause Solder Defects

Discover effective techniques and tips for fixing bridging issues in wave soldering to ensure high-quality solder joints and improve your manufacturing process.

Wave Soldering Fixture Maintenance: 5 Proven Strategies to Boost Yield & Reduce Costs

Learn how to properly maintain wave soldering fixtures to ensure consistent performance and longevity, with tips on cleaning, inspection, and troubleshooting.

The High-Temperature Revolution in Reflow Soldering Fixtures: The Reign of Durostone and Ricocel Materials

Explore the dominance of Durostone and Ricocel in the manufacturing industry, including their properties, applications, and why they are preferred materials for various processes.

Wave & Reflow Soldering: 5 Key Factors to Optimize Soldering Fixtures

Learn how to optimize fixtures for both wave and reflow soldering processes to improve efficiency, reduce defects, and ensure high-quality solder joints.

FR4 vs G10: Flame Retardant Performance and UL94 V-0 Compliance

Explore the flame retardancy properties of FR4 and G10 materials, including their compliance with UL94 V0 standards, and why they are essential in various applications.